Bioplastics for a circular economy

The bioplastics market is expected to grow twice as fast as fossil-based plastics and can replace fossil-based products in most applications. But renewable and bio-based materials are not inherently more sustainable than alternatives (Image by congerdesign from Pixabay)

How compatible are bio-based plastics with a circular economy, and what will it take for these relatively niche polymers to scale whilst achieving sustainable impact on the environment? Advantages and challenges compared with conventional fossil-based plastics are reviewed and assessed in this paper, regarding carbon footprint, natural resources, material properties, recycling properties, cost and market impediments.

Authors

Jan-Georg Rosenboom, Dept of Chemical Engineering, Koch Institute for Integrative Cancer Research, Massachusetts Institute of Technology

Robert S. Langer, Koch Institute for Integrative Cancer research, Massachusetts Institute of Technology

Giovanni Traverso, Department of Mechanical Engineering, Massachusetts Institute of Technology

Highlights

- Renewable and bio-based materials are not inherently more sustainable than alternatives. How a material is made, where it is used and how it can be treated as waste, all determines the overall sustainability performance of the material.

- Life cycle assessment (LCA) is the tool of choice to determine various environmental impacts (e.g. carbon footprint, water use, waste generation) of any material, including plastics.

- Plastic production has a significant carbon footprint of more than 2% (latest estimate is 4.5% per Nature Sustainability 2022).

- The bioplastics market is expected to grow twice as fast as fossil-based plastics and can replace fossil-based products in most applications.

- Keys to circularity for bioplastics products, as for fossil plastics, lie in designs that ensure fit with existing recycling technology.

- Biodegradation is no ‘silver bullet’ to curb plastic pollution. Appropriate collection, recycling, reduced plastic consumption and usage of renewable energy for plastic production remain essential to mitigate plastic waste and carbon emissions.

- Gene editing is a promising tool to increase efficiencies in biomass utilization, bioplastic polymerization and depolymerization (for recycling).

- Comparing the sustainability performance of bio-vs. fossil-based plastics requires thorough evaluation to prevent “greenwashing” (misleading sustainability claims).

“Biodegradation is no ‘silver bullet’ to curb plastic pollution and typically ranks as the least desired fate of bioplastics, especially in anaerobic landfill scenarios without gas capture.”

RESEARCH BRIEF

A bioplastic replacement is now available for almost every application of fossil-derived plastics. However, most replacements are more expensive and currently end up landfilled or incinerated. Policy and regulation on plastics production, labelling, waste treatment and trade are fast-moving within the United Nations and on regional regulatory markets, such as the EU, and at national level.

Investors’ growing interest in sustainability adds to the willingness to invest in the bioplastics market. However, such investments remain high in risk due to uncertain demand owing to high prices and undefined end-of-life treatment.

The worldwide annual production of 100% bio-based plastic is currently approximately 2 million tonnes, out of which biodegradable plastic accounts for two-thirds. In comparison, fossil-based plastic production amounts to >380 million tonnes annually. With the expected growth of the global plastics market, the market share of bioplastics is likely to remain low at around 2%. The annual growth rate in global bioplastics is around 4% (some agencies expect this to be 10%), and 18% within packaging.

Not all bioplastics are biodegradable

Bioplastics are made from renewable materials (such as plants), can be biodegradable (not all are, and chemical structure determines degradation speed) and are made partially or completely through biological processes. Currently, 0.02% of global agricultural land is devoted to producing feedstock for bioplastics. Such usage of first-generation biomass is regarded as controversial, due to the ethical concerns related to competition with food resources. Biomass from non-edible waste streams offer a more ethically viable alternative, such as agricultural biowaste or domestic food waste.

Bioplastics can be extracted from polymers directly from biomass, such as starches or lignin, which is a simple and often cost-effective method. Gene editing technology can be used to produce desired forms of PHAs, a promising bioplastic family with commercially relevant properties, such as strength, gas barrier and biodegradability.

Biodegradable plastics made from fossil-derived feedstock are generally not to be classified as bioplastics, although some of them have the potential to be produced from biomass in the future.

“Bio-based replacements are available for almost every fossil-based application; however, these are mostly in small and costly quantities, and do not always have substantial environmental benefits.”

Life-cycle assessment of bioplastics

The environmental footprint of bioplastics can be analyzed through life cycle assessment (LCA) based on international standards for structure, conduct, limitations and assumptions. The EN 16760 standard is specifically detailed for bioplastics.

LCA outcomes depend heavily on assumptions for energy use and processing efficiencies in all production stages, therefore sustainability indicators for the same polymer show quite broad ranges of values.

In many of the LCAs, bioplastics come out with lower global warming potential than fossil-based plastics, but these benefits are often counterbalanced by negative side effects, such as feedstock farming, acidification potential and eutrophication (due to increased fertilizer and pesticide use). These aspects are believed to be resolved with improved farming practices.

“Use of renewable resources alone does not imply sustainability. Sustainability is highly dependent on how a material is made, where it is used and how it can be recycled, and less so on the building blocks of a material.”

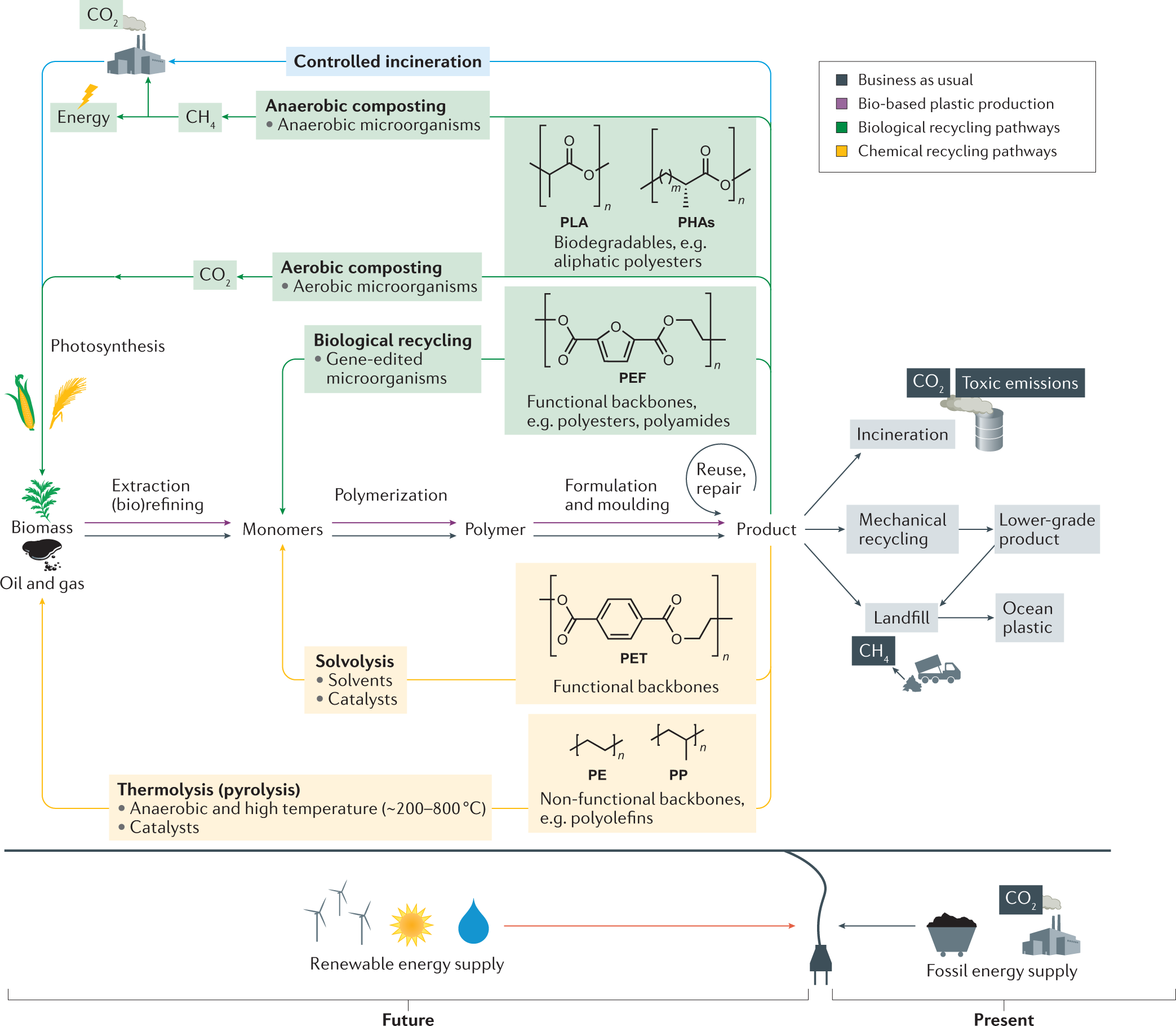

Figure 1: Illustration of the circular plastic economy (Source: Rosenboom, Langer & Traverso, 2022).

End-of-life treatment options for bioplastics

- Mechanical recycling is the simplest, cheapest and most common form of recycling of plastics. However, mechanical recycling of bioplastics is generally not yet commercially available, and often comes with drawbacks in terms of reduced material quality, as well as the inability to remove contaminants and additives. The sorting of novel types of bioplastics also raises concerns of higher rejection rates. Spectroscopic techniques and artificial intelligence robotics can potentially overcome these hurdles. Simplicity in product design is key to further increase recyclability. Progressive regulation and policy could help incentivize such designs, such as higher fees for less recyclable plastics.

- With chemical recycling, plastics are depolymerized into monomers, which can then be made into new plastics of desired quality, whilst removing impurities in the process. Despite the great potential for circularity and virgin-grade plastic production, these processes require chemicals, heat and much more complex processing than mechanical recycling, which makes optimization of these technologies and scrutiny during LCA analysis crucial to derive benefits in terms of energy demand, emissions and cost.

- Biodegradation and composting of bioplastics are other end-of-life alternatives, involving microbial digestion and metabolic conversion of polymers into carbon dioxide, water and other inorganic compounds. The process of biodegradation is, however, complex. Industrial composters often reject biodegradable plastic items, as their decomposition times exceed typical composting times. International certifications and labels used to identify biodegradable products exist, but revision and global harmonization of the standards is suggested to enable appropriate sorting and treatment.

- Instead of complete biodegradation to carbon dioxide, microorganisms can be used to decompose polymers into monomers, which can then be isolated and directly re-polymerized to virgin-grade plastic. This process is generally called biological recycling, and although not yet as well-explored as chemical recycling, it holds potential in providing a cleaner alternative whilst resulting in the same end-product.

- Incineration is a common end-of-life treatment for plastics. Combusting bioplastics based on renewable biomaterials results in a net-zero release of the fixated carbon dioxide (the process-related emissions are still contributing to global warming), whilst thermal energy can be recovered and utilized in the process. Some elements in bioplastics, such as additives may result in toxic compounds in the combustion effluents, which then requires costly capture and treatment technology.

- A similar outcome is achieved when biodegradable bioplastics are subjected to controlled anaerobic digestion, which produces biogas (methane) that can then be utilized as heating gas, emitting carbon dioxide.

- Landfills remain the dominant waste disposal option in many countries, and if mismanaged, they are considered a major source of environmental pollution. As biodegradable polymers compost anaerobically to methane gas similar to food waste, they should be kept out of landfills.

Subheading

text

“quote”

The full article is available here. (link)

Supplementary material to the article available here. (if any)