CIMPA: Towards a circular economy where plastic films don’t go to waste

Multilayer plastic films are materials with unique barrier properties making them key in the food packaging industry (2 million tons of such films are being used globally every year). Not only ensuring a longer shelf life to food products, multilayer plastic films are also widely used at earlier stages of the food value chain. In the agriculture sector, the purpose of plastic film ranges from moisture protection and water conservation to weed control, to pest attraction or repelling.

Yet, multilayer films have so far been developed with a sole focus on their barrier performance, without taking into account their recyclability. Due to a lack of economically and environmentally sustainable recycling solutions, 2.6 million tons of multilayer film waste are being incinerated (66%) or landfilled (34%) globally every year. As a consequence, more than 3 billion euros of value is lost to the economy annually.

CIMPA (A CIrcular Multilayer Plastic Approach for value retention of end-of-life multilayer films) is developing a recycling value chain for multilayer films from food and agricultural applications, with the aim to retain from 12% up to 72% of their value yield. This is based on a synergetic approach combining:

- Innovative compositional sorting, combining Near InfraRed (NIR) and digital watermarking sorting);

- Mechanical and physical (dissolution) recycling;

- Decontamination processes;

- Upgrading (advanced scCO2-based decontamination, properties tuning) solutions.

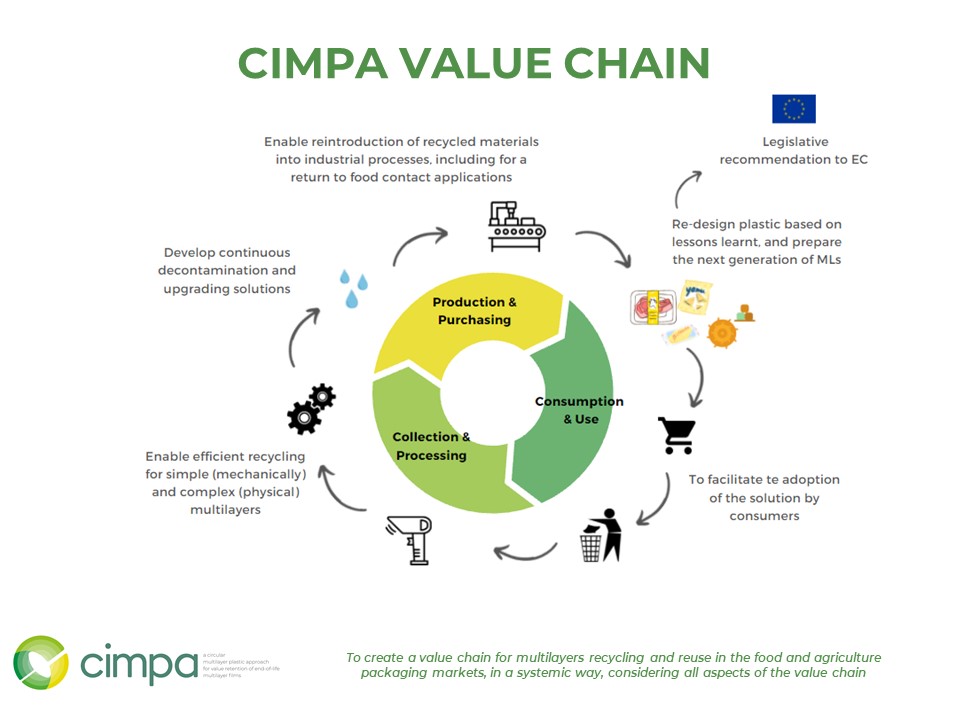

The CIMPA value chain

Through these processes, up to 2.34 million tons per year of recycled materials will be saved and reintroduced into the production chain to substitute for newly sourced virgin materials. A key objective of the overall process will be to produce recycled materials that are compliant with both agriculture standards and food safety regulations and standards.

A challenge test will be submitted to the European Food Safety Authority (EFSA) to validate the performances of the decontamination process, to ensure the concentrations of surrogates are not causing any risks to human health. Environmental, health, safety and cost-benefit assessments of the developed solutions will be conducted based on life-cycle assessment and life-cycle cost analyses. A regulation survey and a Social Sciences and Humanities methodology ensuring systemic engagement and acceptance of all actors along the value chain will be implemented for a widespread integration of the solutions from industry to civil society.

It is foreseen that CIMPA will retain between 0.3 and 2.2 million euros per year of multilayer plastic films value in the economy, and reduce CO2 emissions by 2.1 million tons per year, equivalent to 0.15% of the total annual CO2 emissions from the EU.

To achieve its objectives, CIMPA brings together four experienced Research and Technological Organizations, two cutting edge technology-providing Small and Medium Enterprises (SMEs), one waste management company, three multilayer film producers, one institute for consumer attitude/acceptance studies, one association representing the plastic recycling industry, as well as one consultancy company. The project will last for three years, and is financed through the EU Horizon 2020 research and innovation program.

Follow the progress of CIMPA here.

By Céline Chevallier – CIMPA project coordinator – Materials Development Project Manager at IPC – Industrial Technical Centre of the French plastics and composites industry (France)